- 1. What Is Kanban? The Ultimate Guide to Kanban Methodology

- 2. The Core Kanban Principles and Practices

- 3. What Is a Kanban Board? Examples and Usage Guide

- 4. Everything You Need to Know About Kanban Cards

- 5. Ultimate List of Kanban Tools and Software

- 6. Practical Kanban Templates and Examples

- 7. The Complete Guide to Personal Kanban

- 8. Kanban WIP - Work In Progress Limits Explained

- 9. What Is a Kanban Retrospective Meeting?

- 10. Kanban vs. Scrum Comparison Guide

- 11. Glossary of Kanban Project Management Terms

- 12. FAQs

- 1. What Is Kanban? The Ultimate Guide to Kanban Methodology

- 2. The Core Kanban Principles and Practices

- 3. What Is a Kanban Board? Examples and Usage Guide

- 4. Everything You Need to Know About Kanban Cards

- 5. Ultimate List of Kanban Tools and Software

- 6. Practical Kanban Templates and Examples

- 7. The Complete Guide to Personal Kanban

- 8. Kanban WIP - Work In Progress Limits Explained

- 9. What Is a Kanban Retrospective Meeting?

- 10. Kanban vs. Scrum Comparison Guide

- 11. Glossary of Kanban Project Management Terms

- 12. FAQs

What is Heijunka?

The term Heijunka is a Japanese word that means ‘leveling.’ In project management, Heijunka refers to reducing unevenness in production and minimizing overburden for your project team. Instead of creating products in batches, Heijunka involves processing orders according to customer demand. This allows teams to reduce inventory costs by reducing the number of spare goods taking up space when order volume drops.

The idea of Heijunka originated in Japanese car manufacturer Toyota, which was the creator of the modern Lean framework. The company adopted this concept by building cars in an assembly line model that worked according to consumer demand.

There can be lots of reasons why unevenness occurs in production in Kanban teams. Different products require different resources to be completed, for example, while different team members and machines have different capabilities. While there are lots of ways that unevenness can crop up in the production process, Heijunka looks at two specific ways to level it: by volume and by type.

Leveling by volume

Leveling by volume in Heijunka means altering your production process according to the volume of orders you receive. For example, say you run a car manufacturing company, and you receive 1000 orders of petrol cars per month. However, the number of orders you receive fluctuates by week — one week may see you fulfilling 200 orders, while the next sees you fulfilling 500. Leveling by volume means you would pay attention to the overall volume per month and produce your cars accordingly — a simple solution would be to produce 250 cars every week, ensuring that your monthly number is fulfilled.

Leveling by type

Leveling by type, on the other hand, looks at the type of product that your customers order. Using the same example, we may see that your manufacturing company receives orders for both electric and petrol cars. One month, they may receive 750 orders for electric cars and 250 for petrol, so they tailor their production process to build electric cars for the first three weeks of the month and petrol for the final week.

However, customer needs can be changeable, and companies need to be prepared. Say that, during this month, a number of customers change their minds about which type of car they want — 250 customers decide that petrol cars suit their needs better than electric. To avoid electric cars sitting in inventory, leveling by type might see your company producing a number of both electric and petrol cars each week, so they can better respond to changing orders.

Heijunka boards

To implement Heijunka into your production process, it may help to use a Heijunka board or box. This is a simple grid of squares showing time periods vertically and products horizontally. You fill in the products to be created in their relevant boxes according to their time period and use this as a guide to begin production.

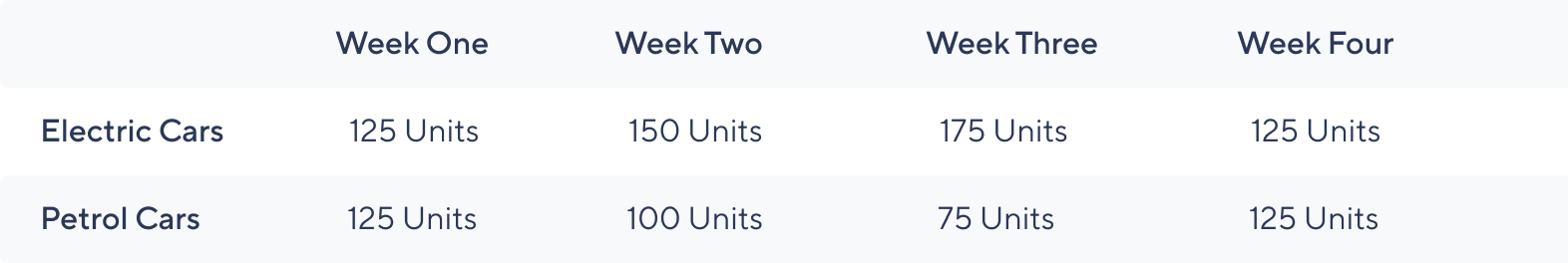

Using our earlier example, a simple template for a Heijunka board may look like this:

As we’ve seen above, the principles of Heijunka can prove very effective in planning and executing a project with minimal waste. For more information on the types of waste in Lean project management, check out our YouTube channel.

Alex Zhezherau

Alex is Wrike’s Product Director, with over 10 years of expertise in product management and business development. Known for his hands-on approach and strategic vision, he is well versed in various project management methodologies — including Agile, Scrum, and Kanban — and how Wrike’s features complement them. Alex is passionate about entrepreneurship and turning complex challenges into opportunities.